Showing all 11 results

-

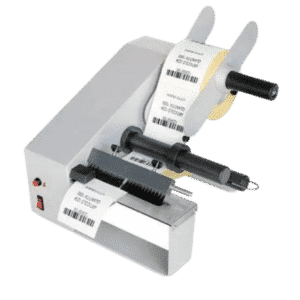

Adhesive label dispenser equipped with mechanical label detection system

Adhesive label dispenser equipped with mechanical label detection system

-

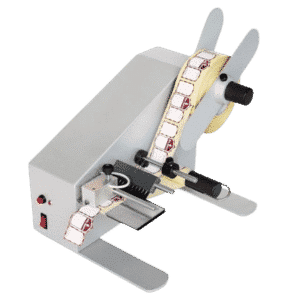

Automatic dispenser for opaque labels

Automatic dispenser for opaque labels

-

High-speed electric dispenser for opaque labels

High-speed electric dispenser for opaque labels

-

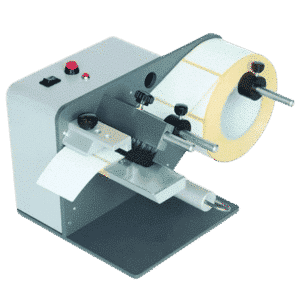

Electric dispenser for all types of labels on rolls

Electric dispenser for all types of labels on rolls

-

High-speed electric dispenser for opaque labels

High-speed electric dispenser for opaque labels

-

Electric dispenser for wide adhesive labels

Electric dispenser for wide adhesive labels

-

Automatic dispenser for wide and long opaque labels

Automatic dispenser for wide and long opaque labels

-

Automatic dispensers for long opaque labels

Automatic dispensers for long opaque labels

-

Compact automatic dispenser for adhesive labels

Compact automatic dispenser for adhesive labels

-

Compact automatic dispenser for transparent labels

Compact automatic dispenser for transparent labels

-

High speed electric dispenser for opaque labels

High speed electric dispenser for opaque labels

Automatic Labeling Machines and Label Dispensers

DERFI offers a wide range of high-speed automatic and semi-automatic labeling machines for every label size whether they are regular or transparent stickers.

Compact Automatic Label Dispensers

Versatile and robust, these convenient machines deliver a seamless experience by dispensing labels at high speed so that a sticker is always ready to be applied regardless of how quickly the operator works. Equipped with a liner recovery system, DERFI’s automatic label dispensers also ensure work surfaces remain clear at all times. While they are engineered to comply with restrictive space standards, these units can accommodate various label sizes, and are available for regular or transparent adhesive labels. Thanks to their advanced detection technology, DERFI’s semi-automatic labeling machines are designed to guarantee optimal levels of productivity to the operators.

Full-Size Automatic Labeling Machines

Designed to reduce the workload of industrial operators, DERFI’s automatic label dispensers are perfectly suited to the repetitive task to dispensing all kinds of labels with the highest accuracy. These machines are tailored to keep up with the demanding pace of professional packaging operations and can handle a wide range of stickers, from bar codes to larger labels intended to provide instructions or indications and even decorative adhesives. Thanks to their automated, uniquely designed liner recovery system, DERFI’s automatic labeling machines wind the paper reel back up as the labels get used at a speed which can reach 5 metres per minute depending on the model. Once a roll is finished, a safety feature alerts the user that they need to replace the roll. The machine remains idle until it detects that the new label roll is perfectly in place.

DERFI’s Unique Automatic Label Dispenser Systems

DERFI’s solutions are designed to peel opaque and clear labels off their liner with great speed and perfect accuracy. In the case of opaque labels, DERFI’s automatic labeling machines are equipped with a photoelectric detection cell connected to the motor. Thanks to its two sensors managed by a microprocessor, the machine is able to detect the difference between the liner and the label itself. The stickers are separated from the paper one by one and, through a fully automated process, the next label is ready well before the user needs to apply it. For transparent labels, DERFI relies on a bespoke solution which enables the machine to make the distinction between the clear sticker and its liner. Where more traditional machines would scan for colour differences, DERFI’s automatic label dispensers for clear stickers make use of electromagnetic sensors. T

hese probes judge the materials on their thickness rather than on their colour and are particularly effective at determining where a clear label is positioned. DERFI’s high quality semi-automatic labeling machines peel the liner away from the label and present it to the operator ready to apply. The time-consuming task of removing the sticker from its liner is therefore no longer necessary. Productivity is enhanced, and operators avoid experiencing MSDs.

DERFI’s Commitments

DERFI’s automatic label dispensers are robust and their mechanical features minimise the risk of malfunction as well as the need for spare parts to be replaced. We aim to provide the best customer experience possible. Our clients can therefore send us a roll of the labels they wish to use, and we will film our tests so they can ensure their automatic labeling machine will work optimally. DERFI can also modify their machine’s standards to adapt them to the exact dimensions of their customers’ label rolls or create custom adhesive cutting and dispensing machines. We also provide a full repair and maintenance service for our automatic label dispensers and all our other machines.