Home > Products > Label dispensers > Electronic label dispensers > For opaque label > LD6025/6050/6100

LD6025/6050/6100

Automatic dispenser for opaque labels

The Labelmoto® LD6025-50-100 is a high-speed electronic sticker dispenser designed for the automatic distribution of labels of all types.

Distributes any type of labels

Automatic rewinding of liner

Robust label dispenser

Deliver parts between 13 and 152mm

Adjustable press brush

Distributes up to 16cm/s

Suitable for intensive production

Detection by photocell

Product variations

Output speed :

LD6025/6050/6100 - Automatic dispenser for opaque labels

Request a quoteThis dispenser peels the adhesive labels off of the liner and presents them one by one to the industrial operator. The LD6050 thus performs the separation of the liner from the adhesive label automatically.

In addition to being a high-performance product, the LD6025 is robust, made entirely of anodized aluminum steel.

The Labelmoto® LD6025-50-100 is divided into three distinct models that differ in the speed of their unwinding: 3.9 cm /s for the LD6025, 8cm /s for the LD6050 and 16cm /s for the LD6100 respectively.

This electric dispenser for opaque adhesive labels is easy to use, saving the user valuable time and quality of work.

Warning! This dispenser is not suitable for transparent labels. The best dispenser for use with transparent labels is the LD6025 C-50C-100 C option (clear label), or refer to the model LD3500.

This automatic adhesive sticker labeler is designed for the unwinding, separating of protective liner and dispensing of labels of all types. It is therefore compatible with labels made of paper, vinyl, foam, etc.

This electronic distributor of adhesive labels is often used in the manufacturing of medical devices, in the mailing industry, and in the labeling of hazardous products and other logistics labels.

It is also a popular device in the food industry for the application of adhesive labels on boxes and cardboard packaging.

The main advantage of this electronic dispenser for adhesive labels resides in the ease with which labels can be presented one by one to the operator. It can be an uncomfortable and especially very tedious task to take labels while separating them from their protective tape. The LD6025 lightens the task of the user by automatically ensuring both the precise dispensing and the separation of adhesive labels from the protective liner. This will allow the user of this device to devote more time to the performance of other tasks.

The liner recovery system is also very ingenious. Thanks to the drive rollers of the device, the liner is directly rewound onto a roll provided for this purpose. The operator’s table or workbench will remain clean from strips of used liner for the duration of use of the Labelmoto®.

The use of this electronic dispenser for adhesive labels is extremely simple and intuitive. Once the machine is running, all the operator has to do is pick up a first sticker and the next one will automatically be delivered.

Another major feature of this automatic dispenser is its distribution speed. As indicated in the table above, depending on the model chosen, the unwinding speed is between 3.9 cm /s and 16 cm /s. The various models in the LD60 range thus meet the flow rate requirements necessary for large scale industrial operations.

Note that this electronic label dispenser allows the user to adjust the label output rate. These can range from 12.7 mm to 152 mm. Such accuracy is made possible thanks to a photoelectric detection cell integrated into the device. The latter ensures the length of the unwinding and detects the dispensing of the labels in order to distribute the following ones.

Additionally, the LD6100 is an automatic dispenser for labels on heavy duty rolls. Indeed, the frame of the device is made of anodized aluminum steel to ensure that the device is protected against wear and tear.

We have already introduced the LD6025 as a versatile device with regards to its compatibility with most types of labels and liner. But the automatic dispenser can also accommodate rolls of various sizes. For a larger version, see the [LDX6025] variant (LDX6025 Product) offering the same features but for wider labels.

This adhesive label dispenser can accommodate label tapes with diameters from 6 mm to 114 mm. The outer diameter of these rolls can reach up to 310 mm.

This automatic label dispenser is also equipped with a dispenser strip that can be adjusted according to the weight and size of the roll of adhesives used. This is manually adjustable by means of a metal knob located on the brush. It thus allows the controlled distribution of heavy rolls.

With the same concern for control and output stability, the LD6050 has a high torque motor which especially comes in handy when using large diameter rolls.

This dispenser is therefore a complete and functional machine, and will offer its user a significant increase in productivity within their assembly line.

Using this automatic industrial label dispenser

Once installed, the Labelmoto is very easy to use. First, set the ON / OFF switch to ON. A first label will be dispensed. Take this first label. A new sticker will then be automatically released..

Starting-up the labeler and loading up a new roll

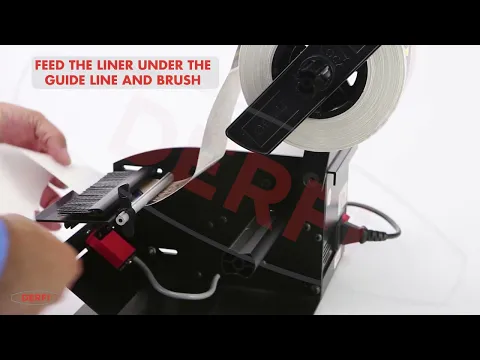

First connect the automatic adhesive label dispenser to a power supply. Then place the roll of labels around the hub, making sure that the adhesive is unwound from the top of the roll. Then grasp the end of the strip and pass it under the guide bar under the brush. Lift the hub so that the label film is tightened. Then accompany the liner under the recovery surface to place it at the level of the drive roller provided for this purpose. Slide the locking rod over the recovery hub to lock the liner and secure the unwinding. Grasp the black plastic locking key on the distribution line above the brush and slide it up to your tape. Once in position, rotate the key clockwise until it locks. Then, simply adjust the angle of the brush using the metal knob to adjust the unwinding resistance.

It is important to position the detection cell at the angle necessary for the full length recovery of the labels.

Labeler cleaning & maintenance

The automatic label dispenser type LD60 requires no maintenance. Depending on the intensity of the activity and materials used on the operating table, clean the device regularly with dry cloths or cleaning wipes.

Spare-parts replacement

DERFI offers the delivery of all parts for this label dispenser also providing repair and maintenance.

Obtain the technical sheet

Receive the technical sheet by e-mail

Discover our video gallery

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.