Comme tous les autres produits de la gamme TDA, le TDA150 se caractérise par son système de dévidement automatique. C’est l’atout principal du dispositif électronique qui propose, pour se faire, 4 modes d’utilisations, imaginés pour répondre aux exigences de chaque opérateur.

Le mode manuel :

Cette fonction est celle qui prête le plus de contrôle, à son utilisateur, dans le rythme et la détermination des longueurs de découpes. Ainsi, celui-ci décidera, au jugé, de la mesure des bandes adhésives qu’il souhaite récupérer, en maintenant appuyée la touche ADVANCE. Une fois cette touche relâchée, le dévidement s’interrompt et l’utilisateur doit alors procéder à la découpe du morceau de scotch en pressant la touche CUT.

Le mode semi-automatique :

Ici, le dévidement manuel est maintenu. De cette manière l’opérateur décidera de la longueur de sa bande en pressant une nouvelle fois le bouton ADVANCE. Ce mode se distingue néanmoins du précédent par l’automatisation de sa découpe. En effet, une fois la touche ADVANCE relâchée, la découpe du morceau de scotch s’effectue de manière autonome par le distributeur automatique.

Le mode automatique :

Dans ce mode, le dévidement de la bande adhésive est entièrement automatique. De fait, la longueur de la découpe se programme à l’avance grâce à la touche de sélection de longueur située en bas à gauche de l’appareil. Le pavé numérique indique alors la mesure de la bande à dévider. Une fois cette mesure définie, le TDA 150 déroule et coupe automatiquement le film adhésif. Après récupération du morceau de scotch, une nouvelle bande sera systématiquement délivrée. Cette fonctionnalité libère son utilisateur de toute action manuelle, si ce n’est la récupération de la bande adhésive.

Le mode à intervalles :

Le TDA 150 propose cette fonction originale qui permet de décider d’un intervalle temporel entre chacun des déroulements. Ainsi, l’opérateur pourra par exemple déterminer de la distribution de morceaux de scotch toutes les 20 secondes. Cela permet à l’utilisateur du dévidoir automatique de pratiquer de multiples tâches sans perte de temps.

L’autre grande particularité de cette machine de découpe d’adhésif à longueur, réside dans son système de coupe à longueur programmable. Ce dispositif permet en effet l’enregistrement d’une unité de mesure contenue entre 40 mm et 9999 mm. Cette fonctionnalité s’utilise uniquement avec les modes automatiques et intervalle. Chaque distribution est alors identique à la précédente, avec une tolérance de dévidement de 1 mm.

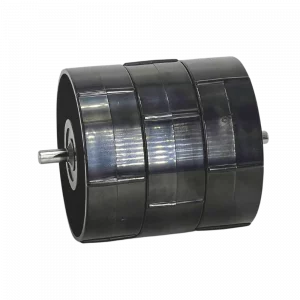

Le TDA 150 est aussi un distributeur de film adhésif électrique très polyvalent. Ses dimensions et sa robustesse permettent l’accueil de bobines de toutes tailles et tous types. Ce dévidoir électronique peut donc accueillir des bobines d’une largeur entre 6 mm et 150 mm. De même, le TDA 150 peut supporter des rubans adhésifs dont le diamètre externe maximal s’étend jusqu’à 251 mm. Il est à noter que ce dévidoir industriel est livré avec 3 moyeux de 76 mm chacun soudés sur un moyeu principal.

Comme énoncé précédemment, il est important de souligner que le TDA 150 peut héberger 3 bobines fines jusqu’à 50mm pour une distribution simultanée.

Concernant la nature des adhésifs, le TDA 150 est compatible avec la majorité des rubans adhésifs et certains films non adhésifs.

Les différentes pièces du TDA 150

La lame du dévidoir électronique, par exemple, est fabriquée à partir d’un acier renforcé. Le TDA 150 peut, en option, être livré avec trois types de lames qui servent chacune la découpe d’adhésifs de natures différentes.

La première est une lame à crans serrés. C’est la plus utilisée pour la découpe d’adhésifs traditionnels. La deuxième lame est munie, quant à elle, de crans épais, pour la découpe de rubans adhésifs plus coriaces. Enfin, la dernière lame est une lame lisse, prévue pour une découpe parfaitement nette.

Les lames du TDA 150 sont fixées à un système de coupe guillotine. Ce mode de coupe assure une découpe lisse et droite en une seule pression. De plus, ce système de coupe est entièrement sécurisé. Le dévidoir automatique dispose en effet d’une cellule de détection photoélectrique programmée pour la reconnaissance de tout corps étrangers tels que les doigts d’une main. Cette fonctionnalité permet l’usage du TDA 150 dans les centres pour personnes handicapées tels que les CAT et ESAT.

Les rouleaux d’entraînement ont eux aussi été pensés et fabriqués pour une découpe fluide et continue des pièces d’adhésifs. Ainsi, les premiers rouleaux sont issus d’un acier renforcé pour résister au temps et à l’usure. Ceux-ci sont accompagnés d’un autre set de rouleaux en mousse pour ne pas agresser l’adhésif et maintenir intacte le haut de la bande collante.

Enfin, le cadre du dévidoir de scotch industriel démontre d’une extrême robustesse. Celui-ci est entièrement métallique et assure ainsi la protection des pièces qu’il abrite.

En cas de panne ou pièces défectueuses, DERFI propose la fourniture et la réparation de toutes les pièces détachables du TDA 150.

Comme indiqué dans la vidéo ci-dessus, il existe en option pour ce dérouleur automatique, un bouton pression pour pied, afin de libérer les deux mains de l’opérateur et lui permettre de remplir d’autres fonctions pendant le dévidement de ses bobines.

Le TDA 150 présente donc toutes les caractéristiques d’un outil multifonctionnel, robuste et très efficace. Il fournit ainsi un gain précieux en temps et en qualité de production.