Home > Products > Tape Dispensers > Automatic tape dispenser > RT7000

RT7000

Automatic programmable adhesive dispenser

The RT7000 is an automatic adhesive tape dispenser specifically conceived for the fast and autonomous dispensing of pieces of tape cut to predetermined lengths.

1-to-2 track dispenser

Robust dispenser

Automatic dispensing

Power 230v/50hz

Output speed 200 mm/s

Suited for industrial production

Photoelectric detection cell

Possibility of loading two different coils

Product variations

RT7000 - Automatic programmable adhesive dispenser

Request a quoteDiscover our video gallery

What makes this electric tape dispenser efficient is its programming system which allows for the input of up to 6 preferred lengths, which are memorized by the device.

This practical and customized distribution of adhesive strips can be achieved while using the automatic mode or semi-automatic mode. This enables the device to be suited to all types of uses on the production chain.

The RT7000 will not only offer considerable time savings to the industrial operator but will also allow for the clean and accurate cut of precisely measured strips of tape.

What use is this programmable electric dispenser for adhesive tapes intended for?

The RT7000 focuses on the fast and automatic cutting of adhesive tapes to length. It is therefore intended for all uses within industrial production, in order to assist the operator whose activity requires the intensive and regular use of adhesive tapes. The RT7000 will is best suited for the assembly of mechanical parts, the closing of cardboard boxes and other rigid boxes, cases, etc… This device will also prove very useful in the leather goods industry (SEO Leather), as well as for the marouflage in the automobile industry.

This automatic dispenser is above all a device for cutting adhesives to length.

Indeed, the BIMA A900 allows the cutting of adhesive tape pieces between 5 and 999 mm with a tolerance of 1 mm. This cutting to length is made possible by the RT7000’s fully automated system, which allows the industrial operator to indicate the desired size on the instrument panel and immediately delivers a piece of tape of the required size.

There are two modes on this automatic double-sided tape dispenser.

The first, the semi-automatic mode, allows the RT7000 user to control the cutting action. By pressing the START button on the electric tape dispenser, a first piece of tape will be delivered through the cassette. This will have to be repeated for a new tape to be dispensed. As for the fully automated mode, it fully assists the industrial operator in the distribution operation. The cutting device recognizes the release of the adhesive strip pieces by means of a photoelectric detection cell. This, once a strip is removed, a second one is automatically distributed, without any manual intervention on the part of the operator. This option is optimized for fast and intensive tape use.

Another great feature of this automatic dispenser for single-sided or double-sided adhesive films, is its programming system.

The user of this automatic electric cutting device can then set up to 6 cutting lengths. The RT7700 allows to alternate between pre-entered cutting lengths in a seamless and effortlessly repetitive way.

These measurements are then distributed and indicated by letters from A to F. Each letter corresponds to a predefined length, allowing the operator to navigate between them and distribute them according to the order of tasks to be performed. In this way, the user of the A900 double-sided automatic dispenser can predefine a length of 20 mm for program A, 30 mm for program B, etc… In addition to its ingenious cut to length system, the RT7000 automatic tape dispenser is also extremely polyvalent.

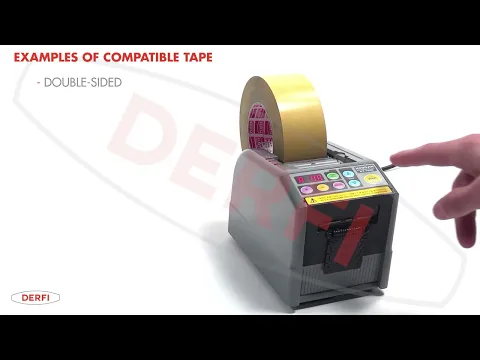

This dispensing device that cuts adhesive strips to length is suitable for all types of adhesive rolls.

Thus, the RT7000 can accommodate adhesive rolls with an outside diameter of up to 300 mm.

In addition, the absence of a chuck allows the use of all hub sizes.

The width of the rolls can range from 6 to 60 mm. For large rolls, an adjustable support system is installed on the back of the unit, thus maintaining the stability of the adhesive dispenser.

One of the greatest advantages of this dispenser is its capability to simultaneously use two rolls adhesive.

A separator is supplied and directly fixed under the device, allowing to place two rolls of different dimensions and materials into the device. This feature will satisfy the industrial operator that needs to handle two different types of adhesives during their missions, or users wishing to work in pairs at the same workstation.

Introduction

The RT7000 is a compact double-sided automatic adhesive dispenser. It allows the user to unwind and cut adhesive tapes and certain types of non-adhesive tapes to the desired length. It is a popular device as it responds to time concerns regarding the time-consuming handling adhesives. Automatic length dispensing is also the best way to avoid unnecessary wastage of adhesives.

Compatible adhesive materials: 3M tapes, Filament, Strong, Acetate Fabric, Glass Fabric, Double-Face, Normex, Pre-stick, Cellophane, Craft, Masking tape, Plastic, and more B.

Compatible non-adhesive materials: Film protection, Paper Tape, insulating film, aluminium foil, copper foil etc.

The RT7000 is a compact double-sided automatic adhesive dispenser. It allows the user to unwind and cut adhesive tapes and certain types of non-adhesive tapes to the desired length. It is a popular device as it responds to time concerns regarding the time-consuming handling adhesives. Automatic length dispensing is also the best way to avoid unnecessary wastage of adhesives. Compatible adhesive materials: 3M tapes, Filament, Strong, Acetate Fabric, Glass Fabric, Double-Face, Normex, Pre-stick, Cellophane, Craft, Masking tape, Plastic, and more B. Compatible non-adhesive materials: Film protection, Paper Tape, insulating film, aluminium foil, copper foil etc.

Starting up the device and loading the roll

Connect the automatic dispenser to a 250 V / 50 Hz socket using the power cable supplied with the device. Then raise the holding roller and place the dispenser in the designated position, making sure that the adhesive is positioned down as the tape is unwound. Feed the tape using the feed button (FWD) until it comes out of the tape dispenser. Close the holding roller and press START to cut the first piece of tape.

Programming

The automatic adhesive dispenser RT7000 has six settings from A to F. These settings remain in memory, and are used to store different preferred cutting lengths. It is not possible to change the order of the programming.

To record a program:

Press the SELECT button to select a program. Once the letter is selected, adjust the desired length by pressing the + and – buttons on the device. For faster value scrolling, press and hold. Press the SELECT button again to move to the next programmable letter.

Semi-automatic mode

Make sure the LED is off. If not, press the AUTO/MANU button. Select the program using the SELECT button. Press the START button to release a piece of adhesive corresponding to the displayed length.

Automatic mode

Press the AUTO/MANU button. A blue LED will light up. Once this mode is engaged, a first adhesive tape will automatically unwind to the measurements according to the length option selected. Once the piece of tape has been released, a new adhesive tape will automatically be dispensed thanks to a photoelectric detection cell. Warning: this mode is not suitable for transparent tapes because they will not be detected by photocell.

Pre-defining a number of cuts

Predefined mode (P-Mode)

This feature allows you to determine the number of strips to be cut with a maximum of 999 pieces. It can be used in automatic and semi-automatic mode.

Using P-Mode:

Select a cutting length with the SELECT button. Press and hold the SELECT button again until LCON appears on the device’s electronic display. Press SELECT again: the scroller then indicates the letter P followed by a number. Set the number of pieces of adhesive tape desired using the + and – buttons on the dispenser. In automatic mode: a new strip will be released each time the previous strip is picked until the counter on the electronic display reads “0”. In semi-automatic mode: a strip will be presented automatically each time the previous one is picked until the end of the defined number of cuts.

Loop mode (L-MODE)

The L-MODE function of the tape dispenser only works with non-adhesive tapes. The number of tape pieces desired can be defined in advance with the maximum number being 999 pieces. The automatic tape dispenser automatically stops when the program is finished.

Using L-Mode:

Use the SELECT button to select a cutting length. Press and hold the SELECT button again to display LCON. Use the + and – keys to set the desired length. Press START, the device will continuously present and cuts the strips until the display on the electronic device reads “0”. To stop the current device, simply press START.

Using two rolls simultaneously

The RT7000 electric adhesive dispenser allows two rolls not exceeding 24 mm wide each to be used at the same time. The separator is located under the industrial tape dispenser, simply position it at the location provided for this purpose.

Holding slot for silicone oil

Dispenser maintenance and cleaning

Since the machine is equipped with blades, extra care should be taken when handling the A900 automatic tape dispenser. The device must be serviced by experienced personnel. A “maintenance level” qualified personnel can assist with the maintenance of the device. Simple daily care can contribute to extending the lifespan of a device: blades should be cleaned using plastic-friendly solvents such as white spirits, greasing the blades will facilitate the device’s cutting action.

Replacement of pieces

DERFI offers constant follow-up for automatic dispensers and provides the different spare parts that compose them. Warning! Make sure the device is switched off before attempting to replace any spare parts.

Obtain the technical sheet

Receive the technical sheet by e-mail

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.