Home > Products > Non adhesive cutters > Heavy-duty > TBC50

TBC50

Programmable automatic duct cutting device

The TBC 50 is one of the most robust and powerful cutters on the market, designed for fast industrial cutting to length.

Cuts to length

Heavy duty device

Hss steel blade

Cuts pieces up to 110mm wide

Adjustable pressure rollers

Cuts up to 140 pieces / minute

Completely programmable

Suitable for intensive use

Product variations

TBC50 - Programmable automatic duct cutting device

Request a quoteThe TBC 50 is one of the most robust and efficient cutters on the market. Intended for the fast and to-length industrial cutting, it is programmable with thermo sheaths, strips and other flat ribbon cable, and non-adhesive film types such as tubulture, Nomex, Velcro etc… The machine can also accommodate thick adhesives with liner.

This automatic Velcro tape cutter draws its efficiency from powerful and precise cutting, dispensing strips that are up to 8 mm thick.

The DSP100, commonly referred to as TBC50, is intended purely for industrial use. Its strength and cutting flow are indicative of an extremely powerful device.

This automatic Scratch Hook cutter is very useful for the cutting of insulating or thermo-retractable sheaths, but also for cutting other materials such as Velcro, flat ribbon cable, Nomex, plastic tubes, electric cables, strips, labels, and many others.

Thus, the DSP100 fits perfectly in factories, workshops and other intensive production lines.

At first glance, this dispenser of plastic strapping differs from other devices thanks to its automatic distribution system. It thus liberates the industrial operator from any manual task while giving them a considerable time saving in their job.

In addition, this automatic sheath cutting machine, once programmed, operates in a fully autonomous manner. It empties and cuts together strips and insulating braids continuously and without intervention by the operator. At the end of the distribution, the TBC50 automatically stops cutting through thanks to a detection bar connected to a microcontact.

The second advantage is in the programmable length cutting option of the device. This flat cable dispenser allows the determination of the number of pieces as well as length of the material to be cut and dispensed. The cuts are therefore fully programmable, partly thanks to a system of electric microprocessors. The programming of the DSP100 is intuitive and is achieved using a digital dial.

The DSP100 can deliver 9999 pieces of 100 millimetres each. This is a major asset for the user looking to save time in the dispensing of plastic strips, and cutting of Velcro sheaths or pieces with identical and regular lengths.

The advantage of this automatic cutting device for non-adhesive flat materials is that it is usable with many materials that are not supported by most traditional dispensing devices. This device is well suited for intensive and industrial applications where Velcro must be cut to length.

Another feature of this sheath cutting device, resides in the speed of its dispensing. The DSP100 one is equipped with a High Speed Steel blade which ensures a high output rate. This enables the DSP100 to up to 140 pieces per minute for a programmed length of 50 mm. Note that the programming system also allows the user to set the flow rate of the dispenser.

This automatic sheath cutting machine allows for an extremely precise cut thanks to its step-by-step motor which guarantees smooth dispensing.

The quality of the cutting is also linked to an adjustable pressure system located on the axis of the guide rollers. This feature allows for smooth and controlled dispensing regardless of the thickness, weight or dimensions of the object to be cut.

Moreover, the DSP100 is compatible with rolls with various dimensions. Thus, it can be used with tapes, strips or other pneumatic bands with a maximum width of 110 millimetres. Similarly, this automatic cutting machine can cut materials that are up to 8 mm thick. Finally, the TBC50 sheath cutting machine is able to cut parts with a diameter of less than or equal to 487 millimetres.

It is also possible to set up several rolls on the same hub depending on thier size. This allows the operator to make use of different materials, or to work with other users on the same device. However, it is recommended to check the tolerance and reciprocity of the materials used.

The DSP100 is therefore a major asset for any industrial operator whose activity is carried out in a large production.

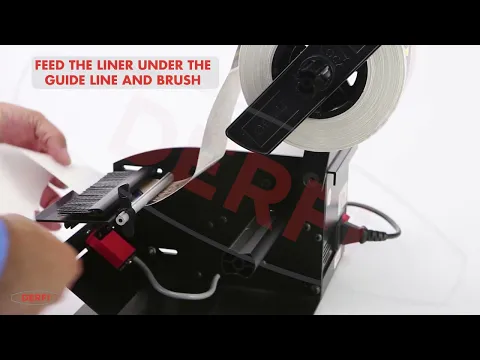

Setting up and loading the roll

First connect the DSP100 to a power supply and press the ON/OFF switch to position it on. Then place the roll of adhesive onto the metal unwind bar, making sure to orient it in such a way that the gap is made from the top. Then place the tape between the two guides provided for this purpose and tighten the knobs to move the tape to the pressure roller. Then press the center bar downwards to lift the rubber roller and slide the end of the strip through it. When primed, program the first cutting advance before proceeding with the first cut. The automatic dispenser is now ready for use.

Programming

The programming of the DSP100 is very intuitive. Each key explicitly describes its action. Just follow the directions on the digital billboard.

Then, decide on the length of the cuts, the number of pieces to be dispensed and finally the speed of dispensing.

Maintenance and cleaning of the dispenser

It is best to have the DSP100 serviced by a professional technician. Handling the internal components of the unit by unskilled people can be dangerous and can damage the unit. Avoid contact with blades and electrical systems.

Replacement of spare parts

DERFI offers the repair and maintenance of this insulating sheaths cutting device. We can also supply all the device’s components.

Request a price offer

Obtain the technical sheet

Receive the technical sheet by e-mail

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.

Our sales team will get in touch with you to help you find the best solution!