Home > Products > Non adhesive cutters > Heavy-duty hot knife > TBC50-H

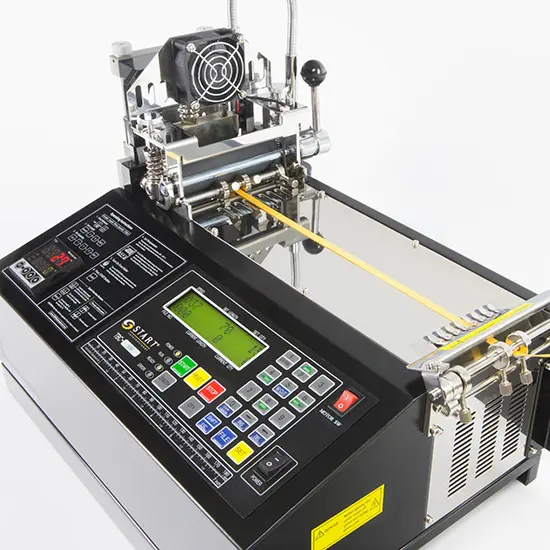

TBC50-H

Hot cutting machine for non-adhesive materials

The TBC50 H is part of the TBC50 series and features a heated blade, making it ideal for hot cutting non-adhesive materials. This ensures clean cuts while preventing fraying.

The TBC50 H is perfect for industrial use, designed for hot cutting of ribbons, straps, belts, tubing, and other non-adhesive materials.

Hot Cutting System

Length Cutting

Adjustable Pressure Rollers

Automatic Stop at the End of the Roll

Suitable for Thin or Smooth Materials

Protected cutting system

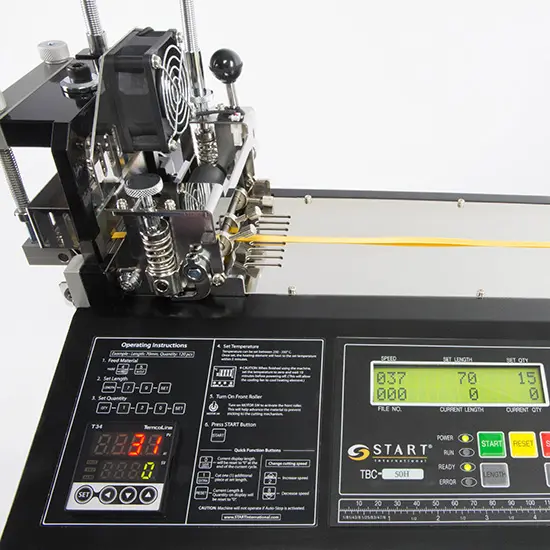

Cutting up to 140 pieces per minute at 50mm

The cutting blade is made of high-speed steel

Product variations

TBC50-H - Hot cutting machine for non-adhesive materials

Request a quoteThe TBC50-H industrial cutter is the ideal solution to prevent fraying of non-adhesive materials such as sleeves and Velcro® films. Equipped with edge sealing functionality after cutting, it ensures clean and quick cuts thanks to its heated knife.

With a throughput of up to 140 pieces per minute and a cutting capacity of up to 6 mm in thickness, this automatic unwinder is perfectly suited for high-speed industrial environments.

Ergonomic and easy to use, it requires no additional tools and guarantees cutting accuracy of ± 1 mm thanks to its stepper motor.

Available at DERFI, a specialist in automatic unwinders for adhesive tapes and labels.

Non-Adhesive Cutting: Non-adhesive films and materials, such as Velcro®, Nomex®, or tubing, are easily unwound and cut using the automatic TBC50-H cutter.

Hot Cutting: With an adjustable temperature, the automatic TBC50-H cutter can process materials that are typically difficult to cut, such as heat-shrinkable or insulating sleeves.

Maintenance of the Unwinder

When maintaining the TBC50-H cutting machine, handling the knives and motors can pose risks to the operator. It is also essential to ensure that the cleaning of the various components does not degrade them. Therefore, it is recommended to contact Derfi maintenance service for this delicate operation.

Listing of Spare Parts to Keep in Stock

For the list of spare parts available to us, please consult us directly.

This automatic unwinder TBC50-H is designed to prevent fraying risks for non-adhesive materials such as sleeves or Velcro® films. It utilizes a heated blade for precise and rapid cutting, suitable for industrial speeds. Easy to use, it ensures a cutting accuracy of ± 1 mm thanks to its stepper motor.

How to Use the TBC50-H Automatic Hot Cutting Machine for Non-Adhesive Materials ?

a) Starting Up and Loading the Reel

Before using the TBC50-H machine, ensure it is properly plugged into the power supply and turned on. The operating temperature can then be adjusted according to the cutting task. It is advisable to wait a few minutes (5 minutes may suffice) for this temperature to stabilize.

Place the reel on the metal bar designated for unwinding. The distribution occurs from the top of the machine; ensure that the reel is correctly oriented before proceeding to the next step.

Next, place the non-adhesive tape between the two guides on the machine, and then tighten the two knobs.

Once all these precautions have been taken, you can proceed to the setup phase: the cutting length can be defined using the LENGTH button and then confirmed with the SET button.

The cutting quantity can be set using the Q’TY button. Again, the SET button allows you to confirm this value.

Finally, by pressing START, the unwinding will begin automatically.

After use, and before turning off the machine, it is recommended to set the temperature to 0°C and run the fan for at least 10 minutes. This helps prevent premature aging of the unwinder.

b) Features of the TBC50-H Non-Adhesive Material Cutting Machine

The TBC50-H automatic cutting machine features a heated knife made of high-speed steel (HSS), enabling it to perform hot cutting of various materials. Thus, belts, straps, and sleeves can be cut without difficulty.

Furthermore, these materials are known for their tendency to fray after cutting. That’s why the TBC50-H industrial cutter includes a system that seals the ends of the strips after cutting, ensuring a clean cut

Thanks to its automatic system, the unwinder detects when the roll is depleted and automatically stops.

For thin and/or smooth materials, it is possible to adjust the pressure applied to the feed roller. This adjustable pressure ensures controlled unwinding of the non-adhesive tape to be cut.

Request a Price Quote

Obtain the Technical Data Sheet

Receive the technical data sheet by email

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.

Our sales team will contact you to assist you in finding the most suitable solution !