Home > Products > Tape Dispensers > Derfi’s safe cut system > Manual tape dispenser > Multi-track > DS2X25

DS2X25

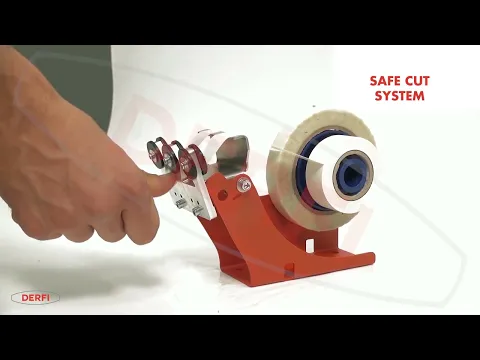

Safe-cut manual dispenser for standard rolls

This two-track dispenser made in France by DERFI is the ideal instrument for any operator wanting to use two types of adhesives.

Cut-to-length dispenser

Safe-cut dispenser

Custom-made roll width

Suited for industrial production

2 Tracks of 25mm

To attach on table

Developed on the basis of a tesa reel

Several hub sizes possible

Product variations

DS2X25 - Safe-cut manual dispenser for standard rolls

Request a quoteIt distinguishes itself from other traditional dispensers due to its sturdiness as well as the quality of its solid sheet metal coating. The DS25x25 is also equipped with a safe-cut system preventing any risk of injury while in operation.

This dispenser was designed for standard use in the production chain. It is perfectly suited to practically all demands linked to industrial activity.

Linking cables

Insulation of electrical components and other…

It is therefore an ideal tool for cutting adhesives to a predetermined length. This is convenient notably for indicative marking on electronic tracks, attaching parts for production, repairing equipment, etc…

The main advantage of this manual dispenser is its double-track mechanism. This enables the operator to use two different types of adhesive tapes at the same time. This is a major advantage on production lines that require the use of adhesives of different dimensions, colour or material. In the automobile industry for instance, it is often essential to differentiate parts by color marking. Likewise for complex wiring systems, it is often useful to group electric cables together and to differentiate them with a color code. The DS2x25 avoids having to change between two dispensers. This enables the operator to save time and gain in productivity.

Another particularity of this manual adhesive dispenser can be seen in its painted sheet metal casing, making the DS2x25 an extremely robust device. This durable coating comes in handy in industrial production environments where the intensive use of equipment causes it to wear down and requires frequent replacement. Standard tape dispensers, are mostly made of plastic and are not very robust, thus making them ill-suited for use in intensive production lines. Dust and dirt – which are often found in industrial environments, often accumulate on tape dispensers thus causeing them to require constant maintenance. The DS2x25, like most DERFI dispensers, resists the wear and tear associated with intensive use over time.

The DS range was designed for compatibility with standard-sized adhesive rolls of 25 millimeters in width, though the DS2x25 can also accommodate smaller-sized rolls. Moreover, it is possible for the industrial operator to select the size of hubs required. This will enable the use of rolls that have different diameters.

Like the single-track model, the DS2x25 is equipped with DERFI’s famous safe-cut system. It is common knowledge that operators tend to injure themselves whilst conducting a repetitive task. The expectations of intensive production force operators to keep to a certain pace in their work which can lead to all sorts of accidents. This manual dispenser, with its safe-cut system prevents the user from getting hurt thanks to its cutting line which is too narrow for fingers to reach. The DS2x25 therefore guarantees smooth-flowing production and risk-free use for operators.

Last but not least, this adhesive dispenser has two fast-cut triangular blades. These blades are not designed to make perfectly neat cuts. For users looking for straight, clean cuts, we recommend consulting the technical datasheets for the DIC50 and the customizable range from the DIC50 to the DC1400. For the same type of two-track dispenser as the DS2x25, but with a clean, neat cut, we recommend the [DS2x25 TB] (page DS2x25 TB) that is equipped with serrated blade.

Using an industrial dispenser for wide rolls of adhesive tape

Setting up and loading the roll

First, mount the DS2x25 onto a work surface or table using the holes at the base of the device that were intended for this purpose. Choose the adhesives and place them around the hubs. Finally, roll the adhesive strips all the way to the triangular blades in order to carry out the first cut.

Maintenance

This device requires little to no maintenance. It is however possible for adhesive residue to accumulate around the blade after long periods of use. Should this be the case, simply clean with some white spirit.

Request a price offer

Obtain the technical sheet

Receive the technical sheet by e-mail

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.

Our sales team will get in touch with you to help you find the best solution!