Home > Products > Adhesives tapes > One-sided tapes > Electrical tape > High temperature resistant tape > Die-cuts > Polyamide die-cut roll B0201M

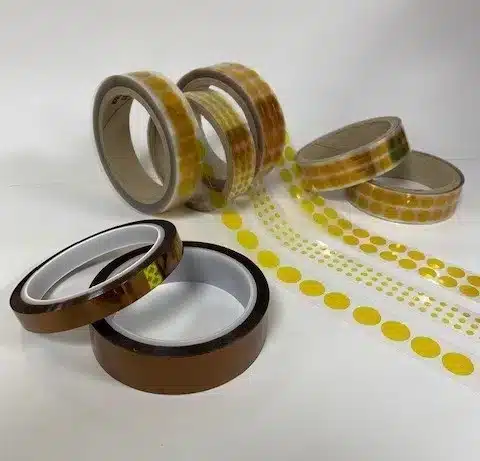

Polyamide die-cut roll B0201M

Polyamide die-cut roll tape B0201M

Polyamide die-cut roll adhesive B0201M

The B0201M adhesive is a polyamide film coated with a high temperature silicone adhesive.

Its main characteristics are high dielectric insulation, coupled with high temperature resistance (240°C continuous and 260°C peak).

It is suitable for masking operations in electronics as well as for holding components in extreme environments.

Excellent electrical insulation

High temperature resistance

Low thickness

Tear and puncture resistant

Resistant to solvents and chemicals

UL510 certified

High temperature acrylic adhesive

Amber colour

Product variations

Polyamide die-cut roll B0201M - Polyamide die-cut roll tape B0201M

Request a quoteWhat is DERFI’s polyamide cutting service?

Die cutting is the process of converting a strip of adhesive into die-cut parts according to a standard or customised die:

– The adhesive roll is placed at the inlet of the machine

– The roll of adhesive is placed at the inlet of the machine and is then unwound to come into contact with an engraved metal cylinder allowing the die cutting of the required shapes

– The surplus is then removed and rewound on an arm of the machine

– Finally, the rest of the material is rewound onto a carrier belt to be wound into a roll

Application conditions

As with all adhesives, surfaces must be clean, dry and free of contaminants (grease, oil, dust, etc.).

Storage conditions

It is recommended that single sided polyimide rolls are stored:

- Flat

- In their original packaging

- Protected from dust, light, moisture and solvents

- At a temperature of 21°C

- At a relative humidity of 50%.

- If these conditions are met, the maximum storage time is 24 months

What cutting formats are possible?

This B0201M adhesive is compatible with die-cutting. We can adapt to your needs in terms of:

– Shapes: squares, discs, customised shapes

– Hollowed out eyelets, hollowed out squares…

– Quantities : we can produce hundreds of thousands of parts, if required!

To facilitate the application of the adhesive, we can also provide gripping tabs.

Electronics: component retention and protection

Because it has a very high dielectric insulation and is very thin, this polyamide film is a versatile adhesive suitable for many electronic applications.

In the form of pads sold in rolls, this material can be used to hold and secure diodes, thermistors, wires and all kinds of components.

Polyimide pads can also be used for temporary protection of circuits, during soldering or simply to prevent dust from settling on connections.

Electronics: wave soldering

Polyamide is an electrically insulating material that is suitable for many electronic applications. The material is temperature resistant and can withstand molten tin. Once cut to the shape of the circuit, it is suitable for masking printed circuits during wave soldering operations.

3D Printing

Polyimide films are commonly used in 3D printing to reduce warping. Once applied to the printer plate, the polyamide film ensures a high adhesion of the first layer. As it is resistant to high temperatures, it can be used to print any plastic material.

Polyimide films for 3D printing are usually supplied in rolls, which may not be practical to apply. Cutting to size allows the film to be cut to the standard dimensions of FDM printer trays, making it easy to use.

Paint masking and electrophoresis

Polyamide is an ideal material for high temperature masking and surface protection. If cut to fit the shapes to be protected, it can be used for epoxy powder coating as well as for electrophoresis.

Power Industry

Silicone-coated polyamide films are commonly used in power electronics, for the insulation of electrical coils as well as in motors or capacitors.

Labelling in aggressive environments

Under certain conditions, polyamide films can also be printed on, allowing labels to be designed for harsh environments by means of die cutting.

This type of label is ideal for the identification of printed circuits in electronics. It can also be used to identify mechanical parts that are exposed to heat, for example in the automotive industry.

Request a price offer

Obtain the technical sheet

Receive the technical sheet by e-mail

Download the full catalog

Discover:

- The whole DERFI range

- The comparison of our solutions

- A set of video for each machine.

Our sales team will get in touch with you to help you find the best solution!