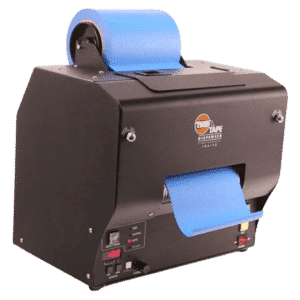

The first benefit of this electric tape dispenser is its automatic dispensing of adhesive tape. As such, four modes are available on this device:

Manual mode:

In this mode, the adhesive tape is unwound by the operator at all stages of cutting. In fact, the operator even controls the adhesive outlet by pressing the ADVANCE scroll button. Then, to finalise the cutting, the user will have to trigger the activation of the guillotine blade using the CUT key.

Semi-automatic mode:

This mode, like the previous one, is used outside of the programmable length mode. The value of the adhesive tape is therefore judged visually by the user. The user of the TDA080 must first press the ADVANCE key in order for the dispenser to deliver the piece of tape. No need to cut manually, the dispenser will automatically cut the adhesive film once the ADVANCE button has been released.

Automatic mode:

Here, the system is fully automated. It is then appropriate for the operator to define the length of the desired adhesive tape using the adjustment button located above the digital panel. Once the length has been determined, simply retrieve the first strip and the second will automatically be delivered. No need for manual interaction in terms of the dispensing or cutting of the adhesive.

Interval mode:

This is one of the main features of the TDA080. It allows the user to define a time measurement corresponding to the interval between the distribution of each strip of adhesive. In this way, a new piece of tape can be dispensed every 10 s, 15 s, 20 s etc, and allow the operator to perform another task during this interval.

In addition, and as mentioned above, it is possible to determine a cutting length. This is a considerable asset for the activity which requires a precise and regular cutting of adhesive tapes. The machine then stores the programmed value, from 40 mm to 9999 mm, using the length selection button. In automatic mode, the electric dispenser will only dispense pieces according to the recorded length. This feature thus represents a significant time saving for its user. It should be noted that the TDA080 ensures a tolerance of 1 mm in the precision of its cuts according to the type of adhesive. For an acrylic foam tape, we recommend the use of TDA080-NS.

Another decisive aspect of this [automatic tape dispenser](Self-adhesive dispenser category) is its capacity to accommodate rolls of different sizes and materials.

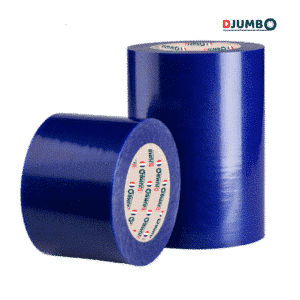

Thus, the TDA080 can accommodate adhesive rolls that are 80 mm wide. This is an advantage that is rare within the various industrial electrical scotch dispensers. In addition, the device is designed to support rolls of adhesive with a maximum diameter of up to 229 mm. Finally, the electronic distributor is supplied with a hub that is 76 mm in diameter. DERFI does offer [custom made](custom manufacturing) hubs with smaller diameters upon request.

Virtually all adhesive types are compatible with this automatic dispenser. Similarly, some non-adhesive rolls can also be supported by the TDA080.

Depending on the thickness of a masking film, it may bend over itself as a result of static electricity. In order to avoid this, DERFI offers a deionizer which can be integrated into the device in order to remove the static charge and release the right length of adhesive film without the risk of the film curling.

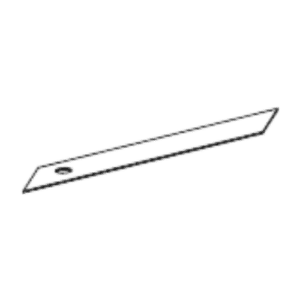

What contributes to the efficiency and robustness of the TDA080 is the quality of its components, starting with the blade.

This tape dispenser can be supplied with three blades of different types and sizes to ensure perfect cutting of any type of adhesive. Thus, the user of the TDA080 will be able to use a blade with tight notches, a blade with wide notches and a smooth blade. All these blades are equipped with a guillotine cutting system that guarantees a clean and straight cut.

In addition, the scotch dispenser TDA080 guarantees a [completely safe cut] (safe cut category). The device is equipped with a photoelectric detection cell which is activated in automatic mode and is used to differentiate adhesive tape from any other object. Thus, cutting will be instantly interrupted when the slightest non-tape object appears on the cutting surface. Thanks to this smart system, the TDA080 is suitable for use in any industry, especially for cabling, [part protection](SEO marouflage), plastic injection, or other activities.

The TDA080 sports a robust frame. It is made from painted steel which considerably increases the life of the device and protects the rest of the detachable parts.

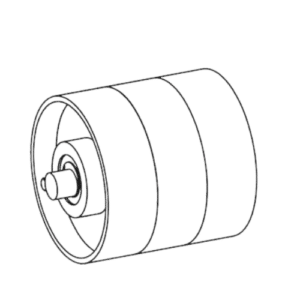

The TDA080 also has metal drive rollers, which are protected by a foam roller for smooth and trouble-free unwinding.

All spare parts for the TDA080 can be supplied and repaired by DERFI.

To conclude, the TDA080 is a real guarantee of performance and demonstrates through all these features, an indispensable potential within an intensive production.

Note that it is possible to add, as an option, an external foot pedal so as to activate handsfree cutting.